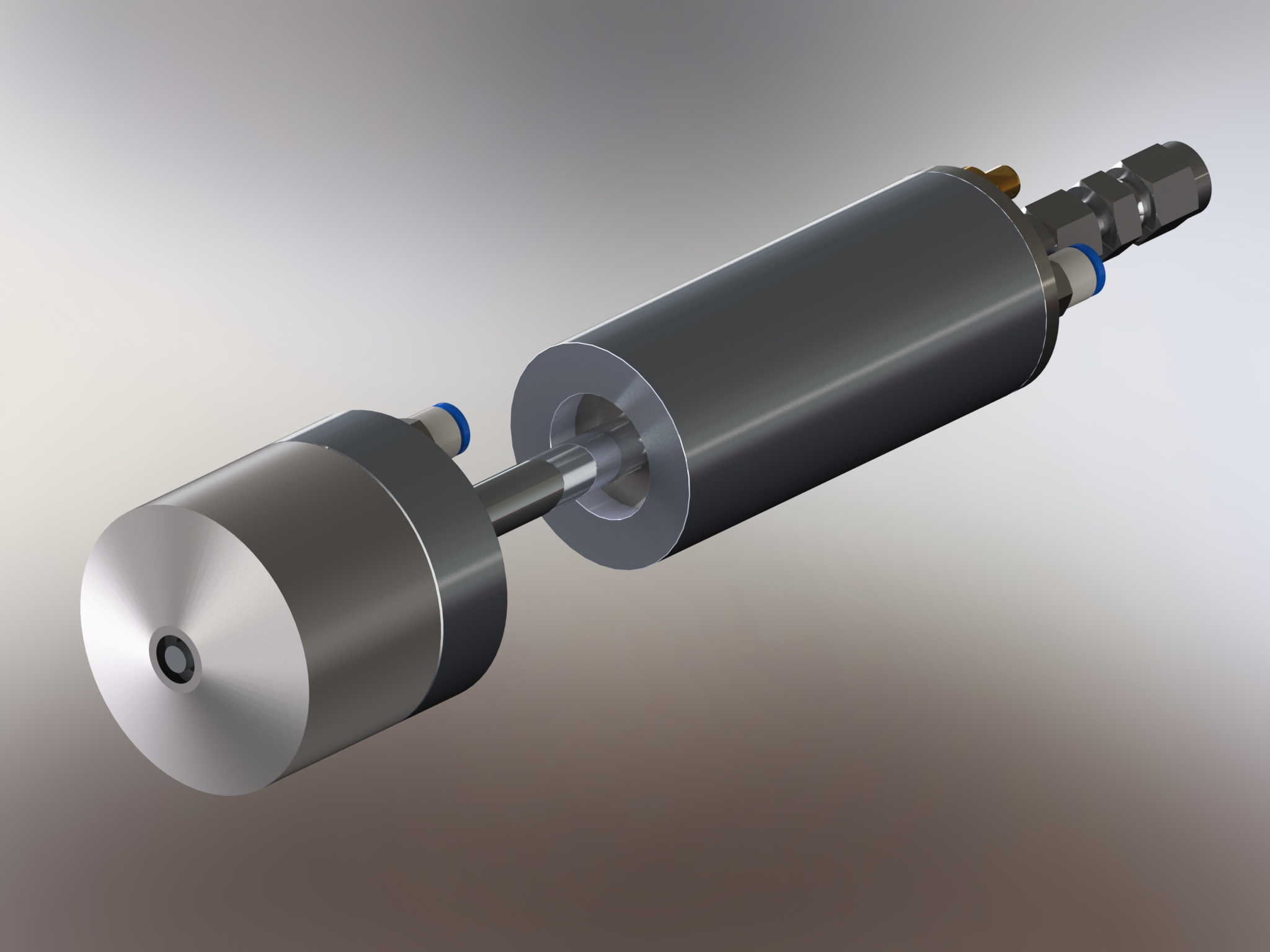

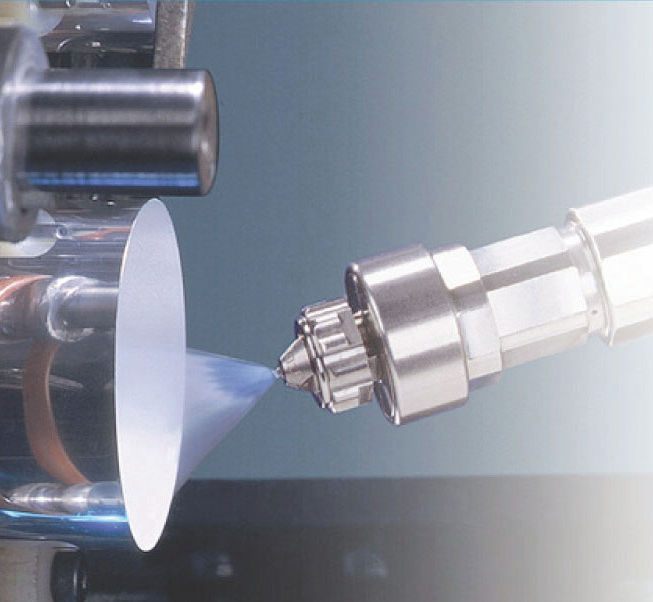

Auto shut off spray gun with spray angle adjustment

|

Harsh Steel Air Atomizing nozzle is a unique two substance nozzle which finds its application in tablet coating, humidifying air products, F.B.D, tracking light heavy oil firing, spray coating, drying etc.

This particular design is available in a flat fan pattern and is efficiently designed to reduce compressed air consumption. This two substance nozzle guarantees a large surface coverage. The spray angle can be adjusted within a range of 10° to 100° max.

The construction of this nozzle is three independent connections each for Air, Liquid and Compressed Air for Auto shut off needle. The precise design of an inbuilt cleaning needle facilitates in quick cleaning of the liquid nozzle outlet. On switching off this compressed air supply the needle closes automatically and abruptly the liquid outlet, thereby avoiding any post dropping.

|

All individual components are available as spare parts. i.e. nozzle bodies, liquid inserts and air caps, needle assemblies etc. The precise manufacturing of replacement parts ensures interchangeability without hampering the spray performance.

Standard connections provided are at 180° apart for Air and Liquid inlets. End connections are 1/4” BSP (F) for Air and Liquid inlets and 1/8” BSP (F) compressed air inlet for Auto Shut off.

Material of construction is S.S. 316, P.T.F.E. and viton.

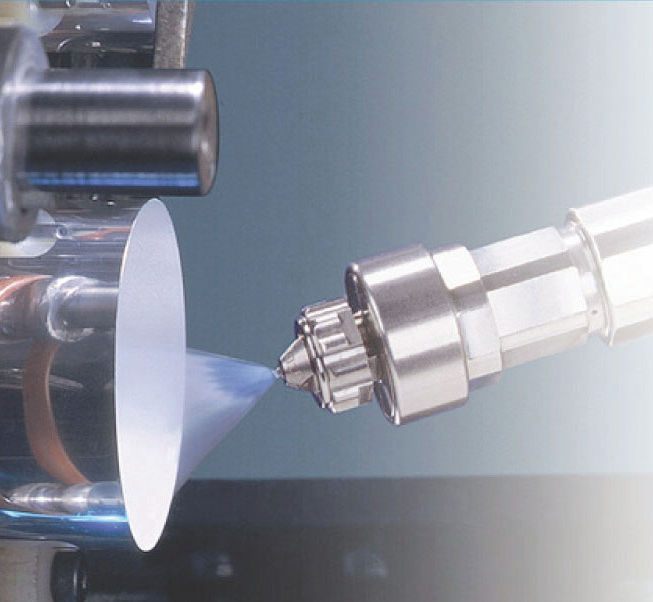

Wurster Coater

Specially designed for applications where large quantities of highly viscous liquids and pastes are required to be finely atomized to mists. Available in a Full Cone pattern with spray angle varying from 20° − 40°. Quality of Atomization can be increased or decreased by adjusting the Air Cap. Auto shut off needle assembly to prevent post dropping. Is made available with desired extended pipe connections on requests. Can be used for Top and Bottom entry in FBP / FBD applications, spray coating, spray drying etc. M.O.C. being S.S.316, P.T.F.E and Viton.

|  |

|

Rear entry air atomizing nozzle

This is a conventional Air Atomizing spray nozzle with the similar working principle, but only a mere change in the body design. The connections here are provided on the back side to facilitate such fitment requirements.

|

Supersonic air atomizing

Harsh Steel supersonic air atomizing nozzle is efficiently designed to atomize very high flow rates. This is a simple conventional design where the air and liquid mixing takes place at the tip of the nozzle and is atomized thereafter. The spray angle achieved is 40° whereas various flow rates can be acquired by altering the nozzle size. Due to large free passage clogging is prevented. End connection: 1/8” BSP (F) − 1/2”BSP (F).

Material of construction mainly S.S.304 / S.S.316.

|  |

|

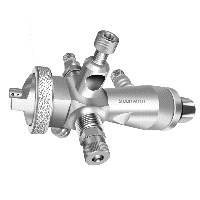

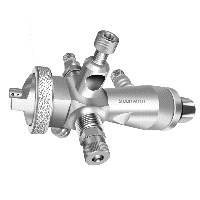

Tablet coating spray gun

This particular design is available in a flat fan pattern. This precision Air Atomizing nozzle was mainly developed for spraying viscous liquids. This nozzle is ideal for atomizing large quantity of liquids in a lesser time. It has 5 independent connections each, for atomizing air, Auto shut off, Fan air and two connections for liquid. The independent atomizing air inlet helps in varying the droplet size without affecting the flow rate. All respective inlet connections are of 1/8”BSP.

|

Tablet coating spray gun

We at Harsh Steel have most recently developed a nozzle for Tablet coating and other processes. It is being widely chosen over other designs mainly because of its compact size. Its design features include an independent connection for fan air where both the flat jet and round jet can be controlled from the outside. A separate liquid connection and an independent Auto shut off connection. The liquid can be controlled and set to a desired position with the control nut provided. The Auto shut off needle prevents post dropping.

|  |

|

Auto spray gun for tile glazing

Harsh Steel Air Atomizing nozzle is a unique two substance nozzle which finds its application in tile glazing. This nozzle provides a very fine Flat spray. There are two inlets for atomizing air and a central inlet for liquid. Material of construction is brass.

|

Tablet coating spray gun

The compact design of this nozzle is better suited for smaller sized coating pans. It has three independent connections each for Air, Liquid and Compressed Air for Auto shut off needle. The precise design of an inbuilt cleaning needle facilitates in quick cleaning of the liquid nozzle outlet. On switching off this compressed air supply the needle closes automatically and abruptly the liquid outlet, thereby avoiding any post dropping.

|  |

|

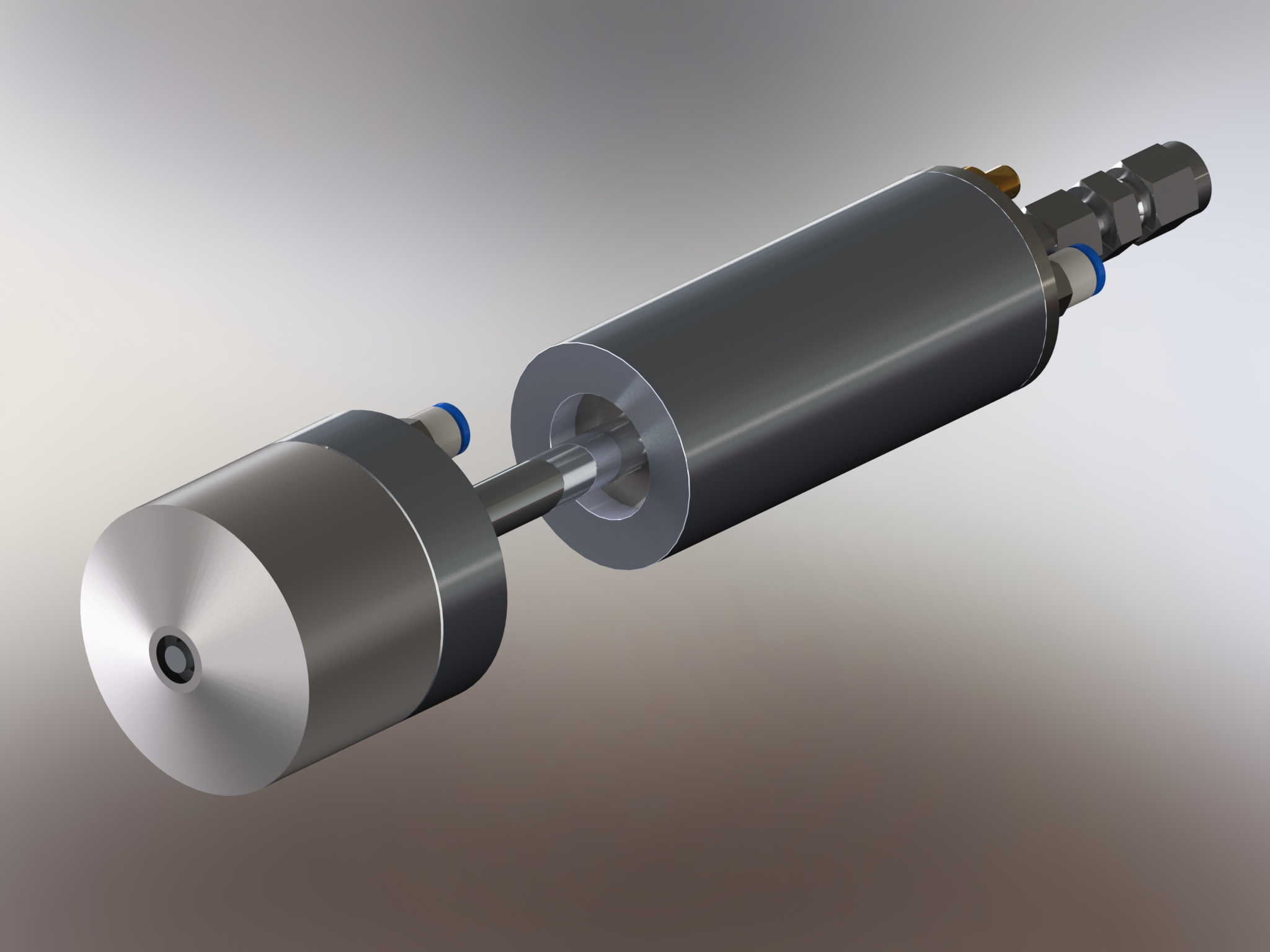

Spray gun with spray angle adjustment

Harsh Steel Air Atomizing nozzle is a unique two substance nozzle which finds its application in tablet coating, humidifying air products, spray coating, drying etc.

This particular design is available in a flat fan pattern and is efficiently designed to reduce compressed air consumption. This two substance nozzle guarantees a large surface coverage. The spray angle can be adjusted within a range of 10° to 100° max.

The construction of this nozzle is two independent connections each for Air and Liquid. The precise design of an inbuilt cleaning needle facilitates in manually cleaning of the liquid nozzle outlet.

|

Rear entry air atomizing nozzle

This is a conventional Air Atomizing spray nozzle with the similar working principle, but only a mere change in the body design. The connections here are provided on the back side to facilitate such fitment requirements.

|  |

|

Supersonic air atomizing

Harsh Steel supersonic air atomizing nozzle is efficiently designed to atomize very high flow rates. This is a simple conventional design where the air and liquid mixing takes place at the tip of the nozzle and is atomized thereafter. The spray angle achieved is 40° whereas various flow rates can be acquired by altering the nozzle size. Due to large free passage clogging is prevented. End connection: 1/8” BSP (F) − 1/2”BSP (F).

Material of construction mainly S.S.304 / S.S.316.

|

Enquiry for Atomizing