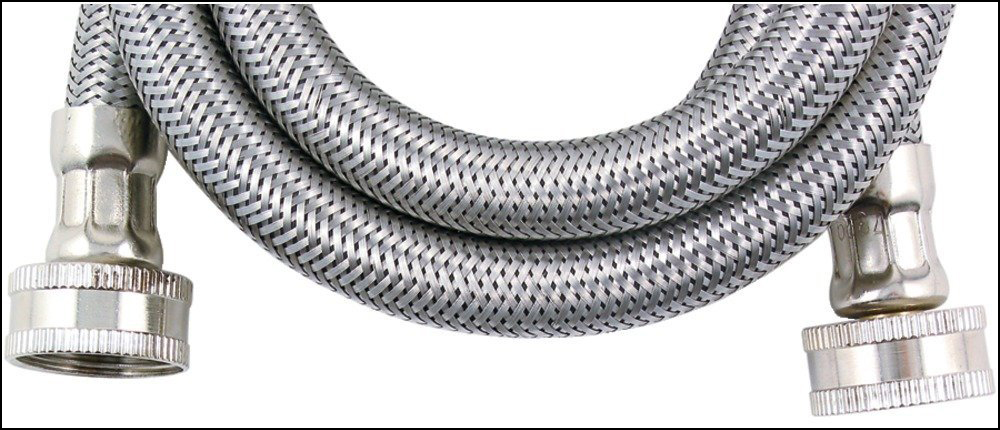

Stainless Steel Hoses

Stainless steel annular corrugated metallic flexible hoses are manufacturing in austantic steel ANSI 321, 316, 316L & 304 grades conforming to BS 6501, Part-1 : 2004 / ISO 10380 : 2003. The annular corrugated metallic hose body provided the flexibility and pressure tight core of the assembly. We also manufacture highly flexible close –pitch hoses for special applications. Stainless steel annular corrugated metallic flexible hose are offered from Size : 1/4"(DN 6) to 12"(DN 300).

Stainless Steel Braids

When pressure is applied, unbraided hose tends to elongate axially; to restrain this, an external layer of SS wire braid is provided. The braid also makes the assembly pressure compatible.

Sometimes two or even three layers of braiding are provided for high pressure applications. The braiding is highly flexible and follows the movement of the hose. The braid is normally manufactured in SS 304 wire. However SS 316 and 321 braids can also be manufactured. We also supply wire braid in different configurations as per customer specifications.

Hose Technical Data : Table - 1

|

Nominal

Size

DN |

Without Braid |

Single Braid |

Double Braid |

Minimum

Bend Radius |

| Max. Working Pressure |

Test Pressure

|

Max. Working Pressure |

Test Pressure

|

Max. Working Pressure |

Test Pressure

|

Static |

Dynamic

|

Inch |

mm |

Kg/cm2 |

Kg/cm2 |

Kg/cm2 |

Kg/cm2 |

Kg/cm2 |

Kg/cm2 |

mm |

mm |

1/4 |

6 |

4 |

6 |

100 |

150 |

160 |

240 |

25 |

100 |

3/8 |

10 |

4 |

6 |

90 |

135 |

144 |

216 |

40 |

150 |

1/2 |

12 |

3 |

4.5 |

80 |

120 |

128 |

192 |

50 |

200 |

5/8 |

16 |

3 |

4.5 |

70 |

105 |

112 |

168 |

50 |

200 |

3/4 |

20 |

2 |

3 |

64 |

96 |

102 |

153 |

70 |

200 |

1 |

25 |

2 |

3 |

50 |

75 |

80 |

120 |

90 |

200 |

1.1/4 |

32 |

1.5 |

2.3 |

40 |

60 |

64 |

96 |

110 |

250 |

1.1/2 |

40 |

1.5 |

2.3 |

30 |

45 |

48 |

72 |

130 |

250 |

2 |

50 |

1 |

1.5 |

28 |

42 |

44 |

66 |

175 |

350 |

2.1/2 |

65 |

1 |

1.5 |

24 |

36 |

38 |

57 |

200 |

410 |

3 |

80 |

1 |

1.5 |

18 |

27 |

28 |

42 |

205 |

450 |

4 |

100 |

0.8 |

1.2 |

16 |

24 |

26 |

39 |

230 |

560 |

5 |

125 |

0.6 |

0.9 |

12 |

18 |

20 |

30 |

280 |

660 |

6 |

150 |

0.6 |

0.9 |

10 |

15 |

16 |

24 |

320 |

815 |

8 |

200 |

0.5 |

0.75 |

8 |

12 |

12 |

18 |

435 |

1015 |

Advantages of Flexible Metal Hose

|

|

High physical strength combined with light weight. |

|

Suitable for wide temperature range (-200° C to + 550°C) |

|

Good corrosion resistance. Resistance to fire, moisture, abrasion and penetration. |

|

Absorbs vibration and noise from pumps, compressors, engines etc. |

|

Compensates for intermittent or constant movement. |

|

Compensates for thermal expansion of contraction of piping. |

|

Corrects problems of misalignment. |

|

A flexible and quick alternative for rigid piping in difficult locations. |

|

|

Stainless Steel Braided Flexible Pump Connectors

|

Stainless Steel Flexible Pump Connectors are designed for mechanical equipment to isolate vibration, relieve stresses, reduce noise, absorb small movements and to facilitate installation. Flexible pump connectors to use suppress vibration from pump, to absorb intermittent lateral movements in pipelines and to compensate for subsidence when pipelines cross building movement lines.

Stainless Steel Flexible Pump Connectors are manufacturing in austenitic steel ANSI 321 (DIN EN 1.4541) & ANSI 316L (DIN EN 1.4404) grades with over ANSI 304 (DIN EN 1.4301) / ANSI 316L (DIN EN 1.4404) single or double wire braided. Hoses conform to BS 6501, Part-1:2004 / ISO 10380 : 2003.

Stainless Steel Braided Flexible Pump Connectors -

Male Threaded / Hexagonal Fixed Male Threaded |

| |

|

Specification |

| Hose Material |

AISI 321 (DIN EN 1.4541) / AISI 316L (DIN EN 1.4404) |

| Braid Material |

AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type |

Single wire braid / Double wire braid for higher pressure |

| Hose Size |

DN 6 (1/4" NB) to DN 100 (4” NB) |

| Hose Length Overall |

10”, 11”, 12”, 13”, 14”, 15”, 16”, 18” |

| End Fittings |

Male fix type SCH 40 pipe threads BSP/BSPT/ NPT threads,

Hexagonal Male fix type pipe threads BSP/BSPT/ NPT |

| End Fittings Material |

CS / AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Working Pressure |

1800 PSI ( 124 BAR ) @ 20° C to 232 PSI ( 16 BAR ) @ 20° C |

| Offset Motion Static |

3/4" to 1/4" |

|

| |

| Stainless Steel Braided Flexible Pump Connectors Flange End |

| |

Specification |

| Hose Material |

AISI 321 (DIN EN 1.4541) / AISI 316L (DIN EN 1.4404) |

| Braid Material |

AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type |

Single wire braid / Double wire braid for higher pressure |

| Hose Size |

DN 15 (½" NB ) To DN 300 ( 12” NB ) |

| Hose Length Overall |

8”, 9”, 10”, 11”, 12”, 14”, 15”, 16”, 18” |

| End Fittings |

Fixed Flange / Swivel Flange as per ANSI B16.5 150#, 300# /

DIN PN 10 / PN 16 / PN 40 |

| End Fittings Material |

CS A105 / AISI 304 (DIN EN 1.4301) A182 / AISI 316L

(DIN EN 1.4404) A182 |

| Working Pressure |

507 PSI ( 35 BAR ) @ 20° C to 160 PSI ( 11 BAR ) @ 20° C |

| Offset Motion Static |

3/4" to 1/4" |

|

| |

| Note: |

- Flexible pump connector are designed the test pressure is 1.5 times of the max. Working pressure.

- The burst pressure is 4 times of the working pressure.

- They are use for full vacuum and operating temperature of -200° C to +700° C.

- Flexible Pump Connectors are not suitable for absorbing AXIAL Movement.

- We are also manufacturing higher pressure Pump Connectors as per customer's specification.

|

| Advantages of Flexible pump connector: |

- Absorbs misalignment, vibration and sound.

- Withstands high pressure.

- Excellent corrosion-resistance.

- Excellent for use with moderate many solvents, chemicals, most oils and grease.

|

Jacketed Flexible Hose

|

Harsh Steel is manufacturing jacketed flexible hose assemblies. The Inner annular corrugated stainless steel flexible metallic hose conveys the fluid and jackets annular corrugated stainless steel flexible metallic hose for heating or coolant fluid or protective the hose and both Inner and jacketed hoses are highly flexible.

We are using our annular corrugated stainless steel flexible metallic hoses ANSI 321 / 316L with ANSI 304 single wire braiding. We will provide both the end flange fittings swivel or fixed type and for inlet & outlet heating or cooling fluid end connection we will provide flange end or threaded end at an offset angle of 180°, Hoses conform to BS 6501, Part-1:2004 / ISO 10380:2003.

Application: Fertilizer Industries, Refineries Industries, Petrochemicals Industries,

Chemical and Pharmaceuticals Industries. |

| |

| Jacketed Flexible Hose Assemblies |

| |

| |

Specification |

| Hose Material |

AISI 321 (DIN EN 1.4541) / AISI 316L (DIN EN 1.4404) |

| Braid Material |

AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type |

Single Wire Braid |

| Inner Hose Size |

3/4" NB 1" NB 2" NB 2.1/2" NB 3" NB 4" NB 5" NB |

| Jacketed Hose Size |

1.1/2" NB 2"NB 3" NB 4" NB 5" NB 6" NB 8" NB |

| Hose Length Overall |

1 Mtr. to 3 Mtr. |

| End Fittings on |

Flange End Swivel Type / Fix Type as per ANSI B16.5 |

| Inner Hose |

150# , 300# / DIN PN 10, 16. |

| End Fittings on |

Flange End Swivel Type / Fix Type as per ANSI B16.5 |

| Jacketed Hose |

150#, 300# / DIN PN 10, PN 16, PN 40 or Fix Male

Threaded BSP/BSPT/NPT. |

| End Fittings Material |

CS A105 / AISI 304 (DIN EN 1.4301) A182 / AISI 316L

(DIN EN 1.4404) A182 |

| Offset Angle |

0° or 180° |

| Jacketed Hose Fittings |

|

| Permissible Operating |

|

Temperature for Inner

& Jacketed Hose |

300° C |

|

Annular Corrugated Metallic Flexible Hose with PTFE Lining

|

|

Harsh Steel is manufacturing annular corrugated stainless steel flexible metallic hose with inner lining of PTFE this hoses are applied for chemical industry, Flexible Hose with plain interior surface PTFE lining are the ideal hose version for application in conveying and filling processes. Hoses conform to BS 6501, Part-1 :2004 / ISO 10380:2003.

We will provide completely PTFE lined smooth interior surface of the metal hose and sealing areas also.

Our PTFE liner is available minimum 2 mm wall thickness and also available 3 & 4 mm wall thickness.

Size: DN 25 (1" ID) to DN 200 (8" ID) maximum length 3 mtr.

Annular Corrugated Metallic Flexible Hose with PTFE Lining |

| |

| |

Specification |

| Hose Material |

AISI 304 (DIN EN 1.4301) / AISI 321 (DIN EN 1.4541)

/AISI 316L (DIN EN 1.4404) |

| Hose Inner Lining |

PTFE |

| Thickness of PTFE Lining |

2 mm to 4 mm |

| Braid Material |

AISI 304 (DIN EN 1.4301) / AISI 316L (DIN EN 1.4404) |

| Braid Type |

Single Wire Braid |

| Hose Size |

DN 25 (1” NB) to DN 200 (8” NB) |

| Hose Length |

0.300 Mtr. to 3 Mtr. |

| End Fittings |

Fixed Flange / Swivel Flange as per ANSI B16.5 150#,

300# / DIN PN 10, PN 16, PN 40 |

| End Fittings Material |

CS A105 / AISI 304 (DIN EN 1.4301) A182 / AISI 316L

(DIN EN 1.4404) A182 |

|

End Connectors

Harsh Steel manufactures various type of end fittings form Carbon steel, mild steel, stainless steel & brass for stainless steel annular corrugated metallic flexible hoses. The end connections are either TIG ( argon ) welded or brazed. |

| |

|

|

|

FIXED MALE (HEXAGON)

HS01 |

FEMALE SWIVEL NUT (UNION) TYPE

HS02 |

FIXED FEMALE TYPE

HS03 |

| |

|

|

|

|

|

MALE UNION TYPE

HS04 |

FEMALE UNION TYPE

HS05 |

900 ELBOW FEMALE SWIVEL TYPE

HS06 |

|

|

|

|

|

|

PLAIN PIPE TYPE

HS07 |

WELDING PIPE (STUB) TYPE

HS08 |

THREADED PIPE TYPE

HS09 |

| |

|

|

|

|

|

| CAMLOCK COUPLING TYPE HS10 |

FIXED RF FLANGE TYPE

HS11 |

SWIVEL FLANGE WITH STUB END TYPE

HS12 |

|

Aplication

Refineries, Power Plants, Steel Plants, Nuclear Installations, Fertilizer Industry, Pharmaceutical Industry, Cryogenic Services, Chemical Industry, Boilers, Paper Plants, Lubrication Systems, Automotive Industry, Steam Hot water Pneumatic Services, Vacuum Systems, Air Conditioning & Refrigeration, Ports & Ship Yards, Defense Industry, Piping, Vibration Absorption, Railways.

Quick Release Coupling

|

| Materials |

| Solid Bar Stock & Chromium Plate Carbon Steel, Brass, S.S.304, S.S.316, S.S. 316L & Aluminum |

| Seals |

| Nitrite, Viton, Neoprene, Silicon, Hypalon etc. |

| Size Range |

| 1/8" To 6" Depending on Type and Material. |

|

|

| |

| Types |

: |

"T" Type - without Check Valve, "V" Type - Single Check Valve, "VV" Double Check Valve. |

| End Connection |

: |

Hose Shank, Flanged, Hose Thread & Socket Weld. |

| Applications |

: |

In Petrochemical & Chemical Industries, Fertilizers, Textiles, Steel Plants, Paper Mills, Machine Tools, Refrigerations etc. |

|

Camlock Coupling

|

| Materials |

| Solid Bar Stock of Mild Steel, Brass, S.S.304, S.S.316 & Aluminum Castings of Carbon Steel Gunmetal & Bronze or as per Customers Requirements. |

| Seals |

| Nitrite, Viton, Neoprene, Silicon, Hypalon etc. |

| Size Range |

| 1/2" To 6" Depending on Type and Material. |

|

|

| |

| Type |

: |

HoseShank,Flanged,PipeThread&SocketWeld. |

| Working Pressure |

: |

1/2" To 2" -35 Bar, 3" To 4" -15 Bar, 5" To 6" -6 Bar |

| Temperature |

: |

-40° C TO +350° C |

| Applications |

: |

In Petrochemical & Chemical Industries, Fertilizers, Textiles, Steel Plants, Paper Mills, etc. |

|

Hoses For Fertilizers & Chemical Plants

| Oil Suction & Discharge Hose / Water Suction & Discharge Hose, Chemical Suction & Discharge Hose |

| Construction |

: |

Inner Tube Resistant Oil / Chemicals, Textile Reinforcement with Embedded Steel wire Helix, Rubber Cover Resistant To Weather, Oil and Abrasion |

| Temp. Range |

: |

-20° C To +80° C |

| Working Pressure |

: |

Up to 20 Kg/Cm2. |

| Application |

: |

Air, Water, Oil & Chemical. |

| End Connection |

: |

Can Be Manufactured As Per Customer's Specifications / Built In M.S. Nipple & Flanges / Built In Fully Rubber Covered Type Flanges |

| Size Range |

: |

1" TO 8" I.D. |

|

|